A Complete Guide to Marine Plywood Grades, Sizes, and Applications

A Complete Guide to Marine Plywood Grades, Sizes, and Applications Marine plywood is a specialized type of plywood designed to withstand moisture, humidity, and harsh environmental conditions, making it ideal for boat building, outdoor furniture, and other water-exposed applications. Its unique composition and adhesive quality ensure durability, structural integrity, and long-lasting performance even in challenging environments.

Shandong Xingang Group Co., Ltd. has been at the forefront of the wood industry’s eco-friendly and innovative material solutions. Their proprietary Xingang Bio-Glue contains 0 formaldehyde, 0 benzene, and no harmful substances, and has been successfully applied in bio-inspired decorative panels, ultra-thin MDF, and bio-inspired marine plywood. This ensures that Xingang plywood is not only environmentally friendly but also offers antibacterial, antiviral, and high-performance characteristics.

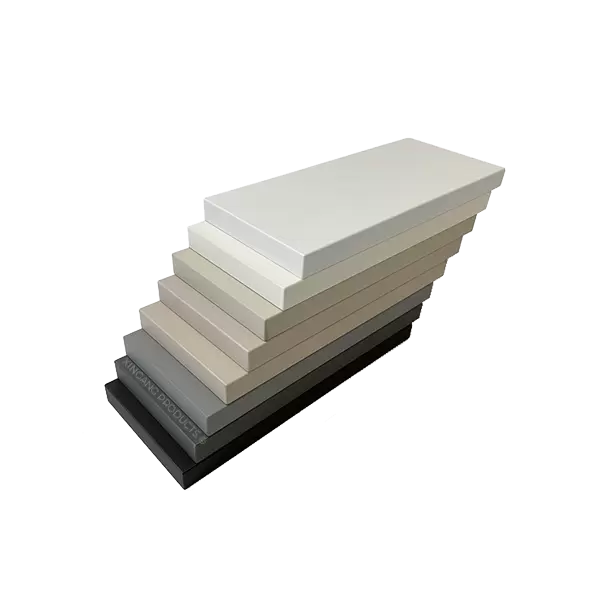

1. Understanding Marine Plywood Grades

Marine plywood is graded based on veneer quality, adhesive type, and structural integrity. Common grades include:

Grade A: Premium face veneers, smooth surface, minimal defects; ideal for visible applications where aesthetics matter.

Grade B: Slightly lower-quality veneer with minor defects; typically used in structural components not visible externally.

Grade C/D: More knots and defects; generally used for non-structural or hidden applications.

Shandong Xingang Group’s marine plywood uses high-quality veneers bonded with bio-inspired adhesives, ensuring the highest durability while meeting green material standards.

2. Common Marine Plywood Sizes

Marine plywood is manufactured in various standard sizes to suit construction and manufacturing needs:

Thickness: Typically ranges from 6mm to 30mm, depending on load-bearing requirements.

Sheet size: Standard sheets are usually 4x8 feet (1220x2440mm), but custom sizes are often available.

Custom cuts: Manufacturers like Xingang can provide tailored dimensions for specialized applications, reducing waste and ensuring precise fits.

Correct sizing is essential for optimizing material usage, structural stability, and installation efficiency.

3. Key Applications of Marine Plywood

Marine plywood’s moisture resistance and durability make it suitable for a wide range of applications:

Boat building: Hulls, decks, and cabin structures benefit from marine plywood’s strength and water resistance.

Outdoor furniture: Tables, chairs, and garden fixtures can withstand exposure to rain and humidity.

Construction projects: Exterior wall sheathing, flooring, and roofing in humid or coastal areas.

Interior decorative panels: With bio-inspired adhesives, Xingang marine plywood is ideal for antibacterial and eco-friendly interior panels.

By integrating marine plywood with advanced bio-inspired adhesives, Shandong Xingang ensures products that are both high-performing and sustainable.

4. Advantages of Bio-Inspired Marine Plywood

The incorporation of Xingang Bio-Glue and advanced manufacturing techniques offers distinct benefits:

Eco-friendly and non-toxic: Safe for indoor and outdoor use without harmful emissions.

Antibacterial and antiviral properties: Ideal for spaces requiring hygiene and safety.

Durability: Resistant to moisture, warping, and fungal growth.

Versatility: Suitable for furniture, construction, and specialized marine applications.

These features position Xingang plywood as a reliable choice for green construction and sustainable living spaces.

5. Choosing the Right Marine Plywood

When selecting marine plywood, consider the following factors:

Intended use: Structural vs. decorative applications.

Environmental conditions: Exposure to water, humidity, and temperature fluctuations.

Grade and veneer quality: Affects strength, aesthetics, and longevity.

Adhesive type: Eco-friendly adhesives like Xingang Bio-Glue enhance durability and safety.

Supplier reliability: Partner with manufacturers who prioritize quality, sustainability, and innovation.

Shandong Xingang Group Co., Ltd. exemplifies a supplier that combines advanced manufacturing, eco-conscious materials, and global collaboration to deliver marine plywood that meets these requirements.

Conclusion

Marine plywood is a versatile and durable material essential for water-exposed structures, outdoor furniture, and sustainable interior design. Understanding grades, sizes, and applications is crucial for achieving optimal performance and long-lasting results.

By leveraging bio-inspired adhesives and eco-friendly manufacturing, Shandong Xingang Group Co., Ltd. provides marine plywood that is not only strong and durable but also green, safe, and high-performing. Whether for industrial, residential, or decorative projects, Xingang marine plywood helps create healthier, sustainable, and resilient living spaces worldwide.