How to Choose the Right Film Faced Plywood for Your Building Needs

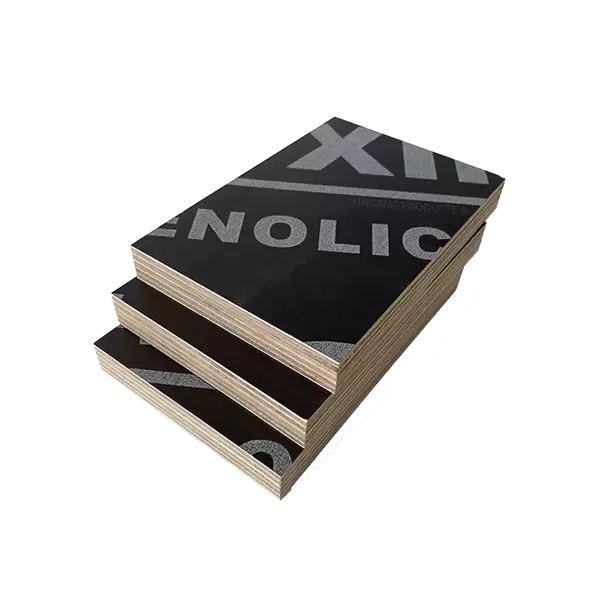

Selecting the right materials is a crucial step in ensuring the success, durability, and sustainability of any construction project. Among the top choices for modern builders is film faced plywood, a versatile material that combines strength, moisture resistance, and a smooth surface suitable for both structural and decorative applications. Understanding its features and benefits can help you make an informed decision for your building needs.

Shandong Xingang Group Co., Ltd. has long been a leader in the eco-friendly wood materials industry. Their Xingang Bionic Adhesive—free from formaldehyde, benzene, and other harmful substances—has been successfully applied in decorative panels, ultra-thin density boards, and marine-grade plywood. This ensures that Xingang plywood products are not only antibacterial and antiviral but also environmentally sustainable while delivering excellent performance.

1. Determine Your Project Requirements

Before selecting film faced plywood, assess the specific requirements of your project:

Application – Is it for concrete formwork, interior furniture, flooring, or exterior use?

Load and Strength – Consider the structural demands and weight-bearing needs.

Moisture Exposure – Choose plywood with adequate moisture resistance for outdoor or humid environments.

Aesthetic Needs – Decide if a smooth, finished surface is required for decorative purposes.

2. Consider Thickness and Grade

Film faced plywood comes in various thicknesses and grades, each suited for different applications:

High-grade plywood – Ideal for demanding structural and decorative uses.

Standard-grade plywood – Suitable for temporary formwork or less exposed applications.

Thickness selection – Thicker panels provide greater strength and durability, while thinner panels are easier to handle and install.

3. Look for Eco-Friendly Adhesives

Sustainability and safety are increasingly important in building materials. Plywood manufactured with Xingang Bionic Adhesive offers:

Zero formaldehyde and benzene content

Safe indoor air quality

Antibacterial and antiviral properties

Choosing eco-friendly plywood ensures both compliance with environmental standards and the health of occupants.

4. Evaluate Surface Finish and Durability

Film faced plywood features a coated surface that protects against moisture, wear, and impacts. When selecting the right plywood:

Ensure a smooth and uniform surface for ease of finishing or concrete formwork.

Check for durability and resistance to repeated use in construction applications.

Opt for products that offer long-term performance under challenging environmental conditions.

5. Work with a Trusted Supplier

Partnering with a reliable manufacturer like Shandong Xingang Group Co., Ltd. ensures access to:

High-quality, environmentally safe plywood

Advanced manufacturing processes

Expertise in meeting diverse construction needs

Xingang’s focus on innovation and global collaboration ensures that every product meets strict standards for performance, safety, and sustainability.

Conclusion

Choosing the right film faced plywood requires careful consideration of project requirements, plywood grade, thickness, surface quality, and eco-friendly properties. By selecting products that meet these criteria, you can ensure durable, efficient, and sustainable construction results.

With Shandong Xingang Group Co., Ltd., builders gain access to advanced, green plywood solutions that combine high performance with environmental responsibility, helping to create safer, healthier, and more sustainable living spaces.