Sustainable Particle Board Production: Turning Wood Waste into High-Value Products

As global awareness of environmental protection continues to rise, industries are rethinking how to produce materials more efficiently and sustainably. In the wood manufacturing sector, particle board production has emerged as a powerful example of circular economy principles — transforming wood waste into high-value, eco-friendly products that support a greener future.

At the forefront of this transformation is Shandong Xingang Group Co., Ltd., a pioneer in the development of environmentally friendly wood-based materials. Through years of innovation, Xingang has introduced bionic adhesive technologies and sustainable production systems that are redefining what it means to create safe, durable, and green wood products for the global market.

1. From Waste to Resource: The Power of Particle Board

Particle board production is an ideal example of resource optimization in the wood industry. Instead of discarding wood chips, sawdust, and other by-products from sawmills or furniture factories, these materials are recycled and pressed into high-density panels.

This process not only reduces waste but also minimizes the demand for solid wood, helping conserve forests and natural ecosystems. By giving new life to industrial residues, particle board manufacturing plays a key role in sustainable material utilization.

2. Eco-Friendly Adhesives: The Heart of Sustainable Production

Traditional particle board has long relied on adhesives containing formaldehyde and other volatile compounds that can negatively impact indoor air quality and human health. Recognizing this challenge, Shandong Xingang Group developed an innovative solution — Xingang Bionic Glue, a formaldehyde-free, benzene-free, non-toxic adhesive designed for green manufacturing.

This breakthrough technology has been successfully applied to multiple Xingang product lines, including:

Xingang Bionic Decorative Boards

Ultra-Thin Density Boards

Bionic Marine Plywood

By eliminating harmful substances, Xingang’s bionic adhesive technology ensures that its particle boards are antibacterial, antiviral, and environmentally safe, while still delivering excellent strength and performance.

This advancement represents a major step forward in achieving truly sustainable particle board production — where health, safety, and quality coexist seamlessly.

3. Advanced Production Technology and Efficiency

Modern particle board production lines have evolved significantly with the introduction of automation, precision engineering, and intelligent control systems. These innovations improve energy efficiency, reduce material waste, and ensure consistent product quality.

Shandong Xingang Group integrates state-of-the-art process control systems that monitor temperature, moisture, and pressure in real time, optimizing every stage — from raw material preparation to hot pressing and finishing. The result is a highly efficient production cycle that saves energy while maintaining environmental integrity.

Through these technological advances, Xingang is able to scale up production while keeping emissions and waste to a minimum, setting a new benchmark for low-carbon manufacturing in the wood industry.

4. Building a Circular and Green Manufacturing Ecosystem

Sustainable particle board production is more than just recycling — it’s about creating a circular manufacturing ecosystem where every resource is maximized.

Shandong Xingang Group has embedded sustainability into every layer of its operations. From sourcing renewable materials to reusing by-products and implementing clean energy systems, Xingang ensures that environmental impact remains as low as possible throughout the entire production process.

The company’s long-term vision goes beyond product innovation — Xingang is working hand in hand with global partners to build a green home ecosystem, promoting healthier and more sustainable living environments worldwide.

5. High-Value Applications of Sustainable Particle Boards

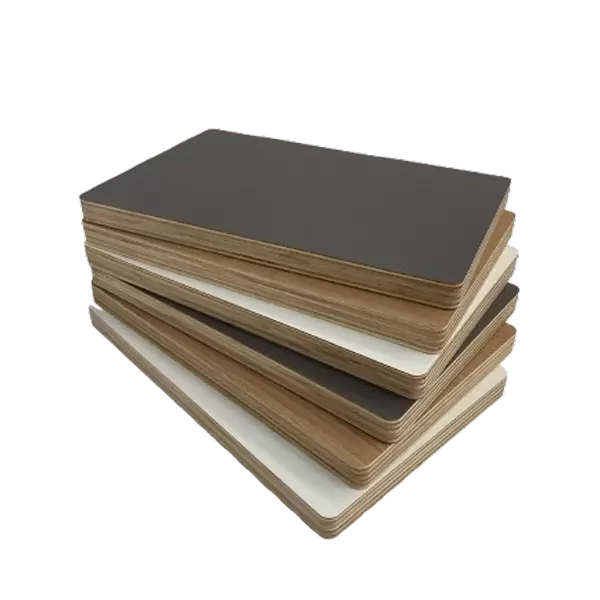

Thanks to continuous innovation in material engineering and eco-friendly adhesives, today’s particle boards are stronger, safer, and more versatile than ever before. They are widely used in:

Home and office furniture manufacturing

Interior wall panels and ceiling systems

Flooring substrates

Decorative boards for green architecture

These applications demonstrate how waste-derived materials can evolve into high-performance, aesthetically pleasing, and health-conscious products, helping both industries and consumers make more sustainable choices.

6. A Shared Vision for a Sustainable Future

As climate change and environmental degradation remain global challenges, Shandong Xingang Group Co., Ltd. continues to push the boundaries of green innovation in the wood industry. By combining scientific research, advanced manufacturing, and biomimetic chemistry, the company is leading the movement toward a safer, cleaner, and more sustainable production model.

With its revolutionary Xingang Bionic Glue and commitment to eco-friendly materials, Xingang is not only transforming the particle board industry but also contributing to a healthier planet and a better quality of life for future generations.

Conclusion

The shift to sustainable particle board production marks a crucial step in creating a circular, resource-efficient economy. Through innovation and environmental responsibility, Shandong Xingang Group has demonstrated that wood waste can be turned into high-value, eco-friendly products that serve both people and the planet.

As the company continues to collaborate globally, its mission remains clear — to create healthier, greener, and more sustainable living spaces, building a future where innovation and environmental stewardship go hand in hand.