Top 5 Advantages of Using Film Faced Plywood in Concrete Formwork

Concrete formwork plays a critical role in modern construction, determining the shape, surface finish, and overall quality of concrete structures. Choosing the right materials for formwork is essential to achieve durable, efficient, and cost-effective results. Among these materials, film faced plywood has become the preferred choice for builders and contractors around the world.

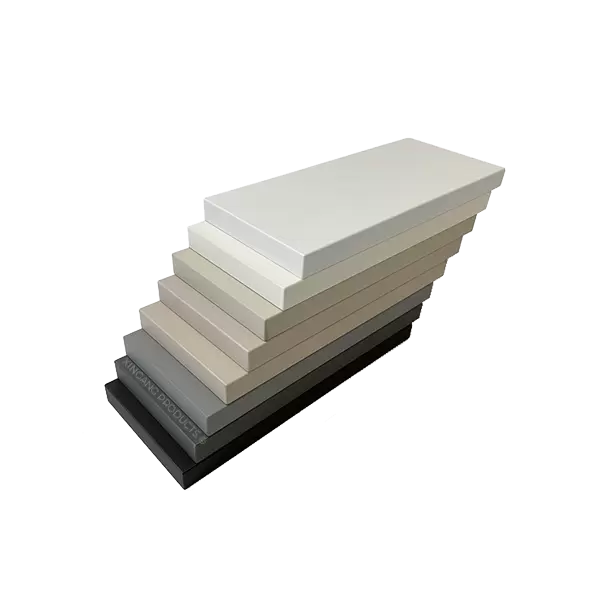

Shandong Xingang Group Co., Ltd., a leading innovator in the wood industry, has been dedicated to environmentally friendly new materials. Their Xingang Bionic Adhesive, with 0 formaldehyde, 0 benzene, and 0 harmful substances, is successfully applied in bionic decorative boards, ultra-thin density boards, and marine-grade bionic plywood. These products are not only green and safe but also antimicrobial, antiviral, and high-performing—making them ideal for demanding construction applications.

Here are the top five advantages of using film faced plywood in concrete formwork:

1. Superior Surface Finish for Concrete Structures

Film faced plywood features a smooth, resin-coated surface that ensures a high-quality concrete finish. Unlike regular plywood, its surface reduces sticking, minimizing the need for sanding or additional finishing work.

With Shandong Xingang Group’s bionic plywood, the smooth coated surface also provides antimicrobial protection, ensuring cleaner handling during formwork installation and improving overall project hygiene.

2. Enhanced Durability and Reusability

One of the main benefits of film faced plywood is its durability. The resin coating protects the plywood from moisture, abrasion, and wear during repeated use. This makes it ideal for multiple concrete pours, saving both material and labor costs.

Xingang’s ultra-thin density boards and marine-grade bionic plywood combine advanced adhesive technology with high-quality wood, offering long-lasting performance even in harsh construction environments.

3. Moisture and Chemical Resistance

Concrete formwork often comes into contact with wet cement, water, and various chemicals. Film faced plywood is designed to resist moisture absorption and chemical corrosion, preventing warping, swelling, and delamination.

Shandong Xingang Group’s bionic adhesive ensures that the plywood panels remain dimensionally stable, even in humid or chemically aggressive conditions, contributing to consistent structural quality and longer formwork life.

4. Cost Efficiency Through Reduced Maintenance

While film faced plywood may have a higher upfront cost compared to regular plywood, it offers significant savings in the long term. Its durability, resistance to damage, and reusability reduce the need for frequent replacements and maintenance.

By using Xingang’s eco-friendly plywood, construction projects can achieve both economic efficiency and environmental sustainability, aligning with modern green building practices.

5. Environmentally Friendly and Safe

Sustainability and safety are increasingly critical in construction. Regular plywood often contains adhesives that release VOCs, which can be harmful to workers and building occupants.

Shandong Xingang Group addresses this issue with their zero-formaldehyde, zero-benzene bionic adhesive, producing plywood that is environmentally friendly, safe, and antimicrobial. This makes their plywood ideal for construction projects that prioritize both performance and health-conscious materials.

Conclusion

Film faced plywood offers unmatched advantages in concrete formwork, including superior surface finish, durability, moisture resistance, cost efficiency, and eco-friendly properties. When combined with innovations from Shandong Xingang Group Co., Ltd., builders and contractors gain access to high-performance, green, and safe plywood products that enhance project efficiency and sustainability.

Choosing Xingang’s bionic plywood for concrete formwork not only improves construction quality but also supports the creation of healthier, more sustainable living and working spaces.