Top Innovations Transforming Modern Particle Board Production Lines

The wood-based materials industry is undergoing a powerful transformation. As global demand for sustainable and high-performance building materials continues to rise, particle board production lines are evolving through new technologies, eco-friendly materials, and intelligent manufacturing systems. These innovations not only improve production efficiency but also significantly reduce environmental impact — redefining what “green manufacturing” means in the modern era.

Among the leaders driving this transformation is Shandong Xingang Group Co., Ltd., a pioneer in the eco-friendly wood materials sector. The company’s dedication to research and innovation has led to breakthroughs such as the Xingang Bionic Glue, a formaldehyde-free adhesive technology that sets new environmental and performance standards for the particle board industry.

Below, we explore the top innovations shaping the future of modern particle board production lines and how Xingang Group is helping build a greener, more sustainable world.

1. Eco-Friendly Adhesive Technologies

One of the most significant advancements in particle board manufacturing is the shift from traditional chemical-based adhesives toward formaldehyde-free bonding solutions.

Shandong Xingang Group’s “Bionic Glue” represents a revolutionary leap forward. This innovative adhesive features:

Zero formaldehyde, zero benzene, zero harmful substances

Strong bonding performance and high durability

Antibacterial and antiviral properties

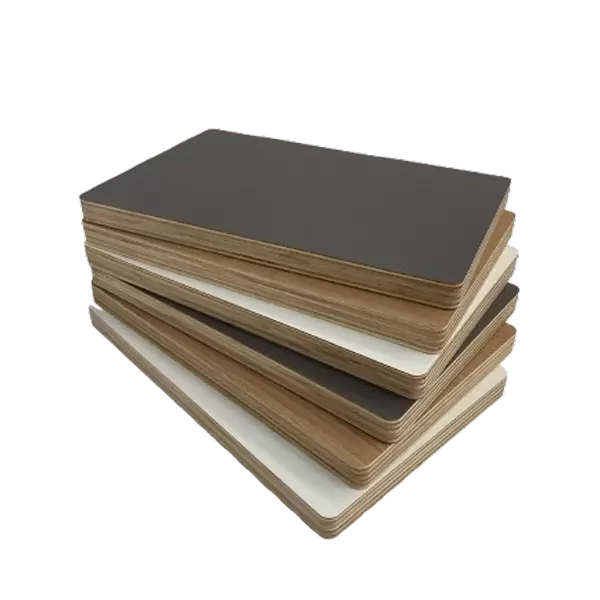

Successfully applied on a large scale to Xingang Bionic Decorative Boards, Ultra-Thin Density Boards, and Bionic Marine Plywood, this technology eliminates the health and environmental risks traditionally associated with synthetic resins.

The result? Particle boards that are not only greener and safer but also stronger and longer-lasting — a true win for sustainable building material innovation.

2. Automation and Intelligent Control Systems

Modern particle board production lines are increasingly adopting automation and smart control systems to enhance precision and efficiency. Through real-time monitoring and digital control, these systems can manage variables such as:

Temperature and pressure during hot pressing

Moisture content during drying

Adhesive distribution and particle size uniformity

Automated production ensures consistent quality, reduced waste, and energy savings, while also minimizing human error. With smart integration, manufacturers can rapidly adjust parameters for different board specifications — enabling flexible, high-efficiency production that meets diverse market demands.

3. Advanced Material Engineering

The quality and performance of particle board depend heavily on the materials used. Modern production lines now incorporate engineered wood fibers, recycled wood residues, and biomass-based additives to enhance strength, density, and environmental safety.

Xingang Group has been at the forefront of this evolution, combining renewable raw materials with biomimetic adhesive systems to create products that are both eco-friendly and technologically advanced. By mimicking the natural bonding mechanisms found in marine organisms, Xingang’s bionic adhesives achieve superior strength while maintaining complete environmental safety.

4. Energy-Efficient Drying and Pressing Technologies

Drying and hot-pressing stages consume the most energy in particle board production. Recent innovations focus on energy recovery systems, optimized air circulation, and low-temperature curing adhesives to minimize energy consumption.

These improvements reduce the carbon footprint of production while maintaining — or even improving — board quality and mechanical stability. Xingang’s continuous investment in energy-efficient equipment reflects its commitment to sustainable, low-emission manufacturing.

5. Sustainable Manufacturing and Closed-Loop Systems

Sustainability is now at the heart of industrial production strategies. Modern particle board plants are embracing closed-loop systems that recycle process water, recover heat, and repurpose wood waste.

Shandong Xingang Group has integrated sustainability into every stage of its operations — from raw material sourcing to product lifecycle management. By utilizing wood residues and developing non-toxic, recyclable materials, the company is helping the industry transition toward a circular economy model.

Through collaboration with global partners, Xingang aims to build a green home ecosystem, promoting a future where environmental protection and industrial innovation coexist harmoniously.

6. Enhanced Surface Finishing and Functional Performance

Beyond structural strength, consumers now demand more from particle board — from antibacterial protection to moisture resistance and decorative appeal. New surface coating technologies and functional additives are making boards more resistant to humidity, scratches, and microbes.

Thanks to Xingang Bionic Glue and advanced finishing processes, Xingang’s boards exhibit superior resistance to bacteria and viruses, ensuring safer use in home and commercial environments. The company’s products demonstrate how aesthetic appeal can be achieved without compromising health or sustainability.

Conclusion: Shaping the Future of Green Wood Manufacturing

From smart automation to bio-based adhesives, the particle board industry is entering a new era of intelligent and sustainable production. Shandong Xingang Group Co., Ltd. stands at the forefront of this transformation — leading the shift toward safer, cleaner, and higher-performing materials.

With innovations like Xingang Bionic Glue and a commitment to environmental responsibility, Xingang is not only redefining particle board manufacturing but also contributing to the creation of a global green home ecosystem.

As the world continues to move toward eco-conscious living, Xingang Group’s vision remains clear: to create a healthier, more sustainable living environment for all, powered by technology, innovation, and a deep respect for nature.