Top Advantages of Film Faced Plywood in Modern Construction Projects

You see film faced plywood in more than half of building projects. It is the top choice for concrete formwork. It has many good points. You get a smooth finish. It is very strong and lasts long. It is also flexible. Many workers pick film faced plywood because it is light. It does not get damaged by water or rot. It gives a clean and even surface with less work. You can use it up to 50 times if you take care of it. Products like the H20 beam from SHANDONG XINGANG GROUP help you get strong and steady results. They also make work faster in tough building jobs.

Key Takeaways

Film faced plywood has a smooth surface and is very strong. This makes it great for concrete formwork. This material is light and bends easily. It is simple to carry and set up at building sites. Film faced plywood can be used 20 to 50 times. This helps save money and cuts down on waste in building jobs. It does a great job of keeping out water. This stops swelling and bending, so it lasts a long time. Picking film faced plywood helps the environment. It is made from wood that is grown in a safe way and uses glue that is better for the air.

Film Faced Plywood: Unique Features

Composition and Structure

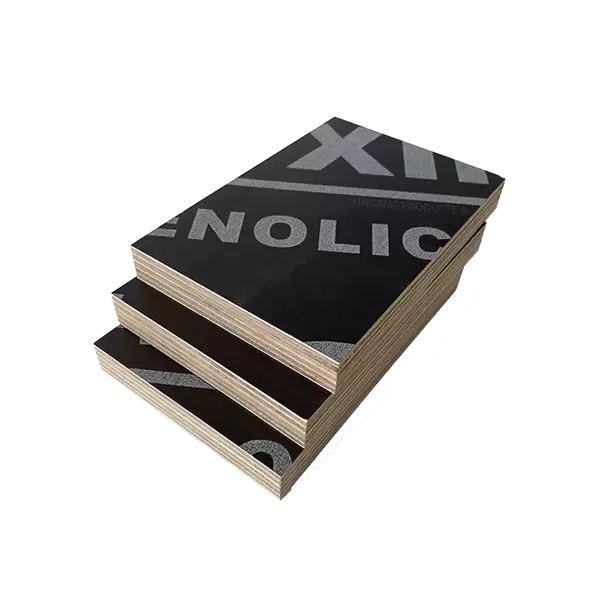

You want to know what makes film faced plywood special. This material has a unique build that gives it strength and a smooth surface. You find several layers inside each sheet. These layers are called veneers. They come from strong woods like birch, spruce, and poplar. Each layer is glued together to make the board tough and steady.

The top layer has a special film. This film is usually made from phenolic resin. It covers the surface and keeps water out. The edges get sealed too. This stops water from getting inside and causing damage. Every sheet meets strict quality standards. You can see the main parts in the table below:

Component | Description |

|---|---|

Veneers | Made from birch, spruce, and poplar veneers. |

Coating | Coated with a phenolic film for durability against wear and chemicals. |

Edge Sealing | Edges are sealed for added protection. |

Quality Standards | Production conforms to strict quality standards. |

This structure helps film faced plywood last longer and stay strong in tough jobs.

Key Benefits for Construction

You get many benefits when you use film faced plywood in your building projects. The smooth surface gives you a clean finish on concrete formwork. The phenolic film stops moisture from getting in. This means the board does not swell or warp. You do not need to spend extra time or money fixing rough spots after you remove the plywood.

You will find that film faced plywood is light. You can move and set it up with less effort. It is also flexible. You can use it in many shapes and spaces. The board does not stick to concrete, so you can remove it easily. This saves you time and keeps your project moving fast.

Tip: Choose film faced plywood if you want a strong, smooth, and easy-to-use material for your next project.

You also get great durability. The board can last 5 to 10 years in heavy-duty jobs. It can hold up to 80 pounds per square foot. This is more than most regular plywood. The waterproof layer keeps the board safe from rain and wet weather.

SHANDONG XINGANG GROUP brings even more value with their innovations. Their plywood uses a bionic adhesive that is safe and strong. The resin-coated surface adds extra protection and a smooth finish. You also get antimicrobial properties for a safer work site. If you need extra support, the H20 beam from SHANDONG XINGANG GROUP gives you high load capacity and easy handling. You can use it for formwork, roofing, and more.

With these features, you can trust film faced plywood to give you the best results in modern construction.

Enhanced Durability and Resistance

Weather and Moisture Protection

You want your building to last in rain, heat, and cold. Film faced plywood is strong and lasts a long time. The phenolic film on top keeps water out. This helps the wood stay safe and dry. The plywood does not soak up water. It keeps its shape and stays strong. Regular plywood can get wet and swell or get weak. Film faced plywood, like WISA-SpruceWR, stops water from getting in. You do not have to worry about it bending or breaking in wet places.

Tests show how well film faced plywood works:

It does not get much thicker after days in water.

It stays strong and bends without breaking.

It holds together after boiling and drying many times.

It stays tough even in hot, wet places.

You can see these results in real buildings. The plywood does not crack or rot. It lasts a long time on every job. You can use the same sheet many times. This saves you money and work.

Load and Impact Performance

You need strong materials for heavy work. Film faced plywood is built to be tough. The layers are glued in a special way. Waterproof glue keeps the board strong. High-density overlay plywood can hold heavy concrete. It does not bend or break under weight.

According to industrial materials expert Robert Mason, “Film Faced Plywood is specifically engineered to perform well in demanding environments, making it a cost-effective solution for projects that need both strength and longevity.”

There are more good things:

The phenolic coating keeps the wood safe from scratches and chemicals.

The smooth top helps pour concrete and keeps the plywood safe.

The film on top stops water and scratches, making it last longer.

The strong build lets you use it again and again.

Each sheet is strong and keeps out water. The plywood can take hits, drops, and heavy loads. You can use it for formwork, floors, and other hard jobs. It lasts longer, so you fix or replace it less. The water resistance keeps your work safe in any weather.

Cost Efficiency and Reusability

Lifecycle Savings

You want to save money and time when you build. Film faced plywood helps you do this. It may cost a bit more at the start. But you save a lot during the whole project. Look at the table below to see how it compares to regular plywood:

Aspect | Film Faced Plywood | Traditional Plywood |

|---|---|---|

Initial Purchase Price | Slightly higher | Lower |

Single Use Cost | 1/5 - 1/3 of traditional formwork cost | Higher |

Labor and Material Savings | 15-20 yuan per square meter | Additional costs for plastering |

Project Management Costs | Reduced due to high turnover efficiency | Higher due to longer construction |

Additional Treatment Fees | None required | Required for anti-corrosion |

Recycling Value | Can be recycled for cash | Not applicable |

Film faced plywood saves you money in many ways. You do not need to pay for extra treatments. You also save on labor and project management. You can recycle it for cash, which saves even more. These savings are important for building projects around the world.

Multiple Uses in Construction Projects

You can use film faced plywood again and again. If you take care of it, you can reuse each sheet 20 to 40 times. Regular plywood only lasts for 2 or 3 uses. This means you buy less and throw away less. You get more out of every board.

You save money because you do not need to buy new boards often.

You finish your work faster since you do not wait for new materials.

You help the planet by using less wood.

Film faced plywood makes building faster and easier. You spend less time fixing or replacing boards. You also get better results in big building jobs. Many builders say they work 20% fewer hours when they use film faced plywood. Some finish their concrete work weeks sooner. This proves that saving money and working faster go together.

Tip: Pick film faced plywood for your next job if you want to save money and work faster. You will notice the benefits in both time and cost.

Sustainability in Construction

Eco-Friendly Materials

When you pick film faced plywood, you help the planet. This material is good for the environment. The wood comes from forests that are managed well. These forests keep growing and stay healthy for many years. The glue used is also safe for nature. Here are some eco-friendly things in film faced plywood:

FSC-certified wood cores

Low-emission adhesives

These choices mean fewer bad chemicals go into the air. You help keep the air clean for people and animals. Using these materials means you support green building in every project.

Environmental Impact

Using film faced plywood is good for the earth. Wood from certified forests helps in many ways:

Forests stay strong and healthy.

You know the wood is legal and safe.

Local people who care for forests get support.

Less cutting of trees means less carbon in the air.

Your project can also meet green building rules. Film faced plywood can help you get points for LEED or BREEAM. These programs give rewards for using safe and smart materials. You can get benefits like:

Proof that shows how the material affects the earth.

Points for using wood from good sources.

Low VOC emissions make the air inside better.

Credits for using strong and long-lasting boards.

When you choose film faced plywood, you help the planet. You show you care about the earth and want to build smart. Your choices help make a better world for everyone.

Versatile Applications in Construction Projects

Concrete Formwork Uses

Many builders pick film faced plywood for concrete formwork. It works well in lots of building jobs. You can use it to make molds for walls, columns, and slabs. The smooth surface helps the concrete look nice. You do not need to fix rough spots as much. The phenolic coating keeps water out and protects the plywood from harm.

Film faced plywood is mostly used for concrete formwork. It helps make molds for things like walls, columns, and slabs. The smooth top stops concrete from sticking. This makes it easy to take off the boards after the concrete dries. The plywood does not get ruined by water. It stays strong even when wet. You can use it again, which saves money and cuts down on waste.

You can use this plywood for many concrete jobs:

The phenolic coating keeps water and scratches away.

It is tough, so it is good for making concrete shapes.

The smooth top helps you get nice-looking concrete.

This plywood can fit many shapes and sizes. You can try new designs in your work. The surface does not stick to concrete. You can take off the boards easily and use them again.

Other Building Applications

Film faced plywood is useful for more than just concrete formwork. You can use it for roofing, flooring, and wall sheathing. It is strong and does not get damaged by water. This makes it a smart pick for these jobs.

Here is a table that shows how you can use this plywood:

Application | Benefits |

|---|---|

Roofing | Keeps out water and is strong against weather. |

Flooring | Holds weight well and lasts a long time. |

Wall Sheathing | Strong for walls and looks nice too. |

Roof panels keep out rain, snow, and wind.

Floor panels hold people and furniture without breaking.

Wall panels are good for prefab buildings and look good inside.

You can use this plywood in warehouses, factories, and even for short-term buildings. Because it works in so many ways, builders like to use it for strong and safe projects.

Comparing Film Faced Plywood to Traditional Materials

Performance Differences

You want to pick the best material for your job. Film faced plywood and traditional plywood are not the same. They each have their own good points. The table below shows how they are different:

Feature | Shuttering Plywood | Film-Faced Plywood |

|---|---|---|

Primary Focus | Strength and durability for structural support | Aesthetics and smooth surface finish |

Typical Applications | Concrete construction, retaining walls, bridges | Furniture making, interior decor, architectural finishes |

Resistance to Water | Moderate, primarily for structural use | High, due to protective film coating |

Surface Finish | Rough, not aesthetically focused | Smooth and visually appealing |

Film faced plywood is easy to spot because it looks smooth. It gives concrete and other surfaces a nice, clean look. The special film on top keeps water out. You do not have to worry about the board swelling or bending when it rains. Traditional plywood does not have this kind of shield. It can get rough and lose its shape if it gets wet.

You can use film faced plywood outside in wet weather. The film layer keeps water away, so it works well in rain or damp places. Metal formwork is strong, but it does not stop water like film faced plywood does.

Tip: Pick film faced plywood if you need something that stays strong and looks nice in wet places.

Value and Longevity

You want your building materials to last and save money. Film faced plywood lasts longer than traditional plywood. The table below shows how many times you can use each one:

Type of Plywood | Average Lifespan | Uses Required for 30 Pours | Total Material Cost Impact |

|---|---|---|---|

Film Faced Plywood | 30+ uses | 1 | Cost drops by over 50% |

Traditional Plywood | 8–10 uses | 3 | Higher total cost |

You can use one sheet of film faced plywood for more than 30 pours. Traditional plywood only lasts for 8 to 10 uses. This means you buy fewer boards and throw away less. Over time, you spend less money on new boards.

The higher price at first is worth it because you do not need to buy new boards often.

You save money on fixing and taking care of the boards.

The strong film on top keeps the board in good shape for a long time.

Film faced plywood gives you great value. It is strong and lasts a long time. It helps you finish your project on time and saves you money. Picking film faced plywood is a smart choice for your building needs.

You get many good things when you pick film faced plywood for building around the world. The table below shows why experts like it:

Advantage | Description |

|---|---|

Durability | Lasts longer than regular plywood. |

Moisture Resistance | Stays strong in wet conditions. |

Cost-Effectiveness | Saves money with many reuses. |

Versatility | Works in many global construction projects. |

You get smooth surfaces that are easy to clean.

The panels do not get damaged by water or chemicals.

You spend less money and throw away less material.

Top builders say to use film faced plywood and the H20 beam because they are strong and dependable. These benefits help you build better and keep everyone safe.

FAQ

What is film faced plywood used for in construction?

You use film faced plywood mainly for concrete formwork. It helps you create smooth walls and floors. Builders also use it for roofing, flooring, and wall panels. This material works well in many construction materials projects.

How many times can I reuse film faced plywood?

You can reuse film faced plywood up to 30 or even 50 times if you handle it with care. Clean the surface after each use. Store it in a dry place to make it last longer.

Does film faced plywood help with energy efficiency?

Yes, film faced plywood helps you improve energy efficiency. It creates tight, smooth surfaces that reduce air leaks. This helps keep buildings warmer in winter and cooler in summer.

Is film faced plywood waterproof?

You get strong water resistance with film faced plywood. The special film layer keeps water out. This means the board does not swell or rot easily, even in wet conditions.

Can I use film faced plywood for outdoor projects?

Yes, you can use film faced plywood outdoors. The protective film and sealed edges help it stand up to rain and sun. You should still check it often to keep it in good shape.