What Do MDF Manufacturers Do? Production Process, Standards, and Quality Control

Medium Density Fiberboard, commonly known as MDF, is one of the most widely used engineered wood products in furniture, interior decoration, and construction. Behind every high-quality MDF panel is a professional MDF manufacturer responsible for transforming raw wood fibers into stable, durable, and environmentally responsible boards. Understanding what MDF manufacturers do, how MDF is produced, and how quality is controlled helps buyers and designers make more informed sourcing decisions.

The Role of MDF Manufacturers

MDF manufacturers specialize in producing engineered wood panels by breaking down wood into fibers, bonding them with resins, and forming uniform boards under heat and pressure. Their role goes far beyond basic production. Professional manufacturers are responsible for material selection, process optimization, environmental compliance, and performance testing to ensure MDF panels meet the requirements of different applications.

From furniture and cabinetry to decorative panels and interior wall systems, MDF manufacturers must deliver products with consistent density, smooth surfaces, and reliable mechanical strength.

MDF Production Process Explained

The MDF production process begins with raw material preparation. Wood residues such as logs, chips, or recycled wood are carefully selected and processed into fine fibers. This step is critical for achieving uniform density and stable board structure.

The fibers are then dried to a controlled moisture level before being blended with adhesives and additives. The choice of adhesive has a major impact on both performance and environmental safety. Traditional MDF often relies on formaldehyde-based resins, while advanced manufacturers are increasingly adopting innovative, eco-friendly bonding technologies.

Next, the fiber mixture is formed into a mat and pressed under high temperature and pressure. This hot-pressing stage bonds the fibers together, determines board thickness, and ensures structural integrity. After pressing, the boards are cooled, trimmed, sanded, and cut to standard or customized sizes.

Standards and Certifications in MDF Manufacturing

To ensure safety and quality, MDF manufacturers must comply with various international standards. These standards typically cover density, bending strength, internal bond strength, moisture resistance, and formaldehyde emission levels.

Common requirements include compliance with E0 or E1 formaldehyde emission standards, as well as regional regulations such as CARB and EPA standards for indoor air quality. Certifications like FSC also demonstrate responsible wood sourcing and sustainable forest management.

Adhering to these standards is essential for MDF used in furniture and interior applications, where environmental performance and human health are key concerns.

Quality Control in MDF Manufacturing

Quality control is a core responsibility of professional MDF manufacturers. It begins with raw material inspection and continues throughout the entire production process. Manufacturers monitor fiber size distribution, moisture content, pressing parameters, and surface quality to maintain consistent results.

Finished MDF panels undergo mechanical testing, dimensional stability checks, and emission testing to verify that they meet both performance and environmental requirements. Advanced quality management systems help manufacturers identify defects early, reduce waste, and deliver reliable products batch after batch.

Innovation and Environmental Responsibility

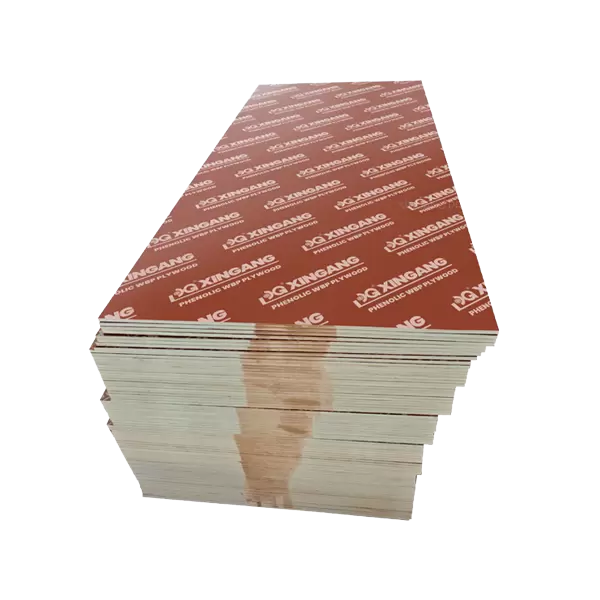

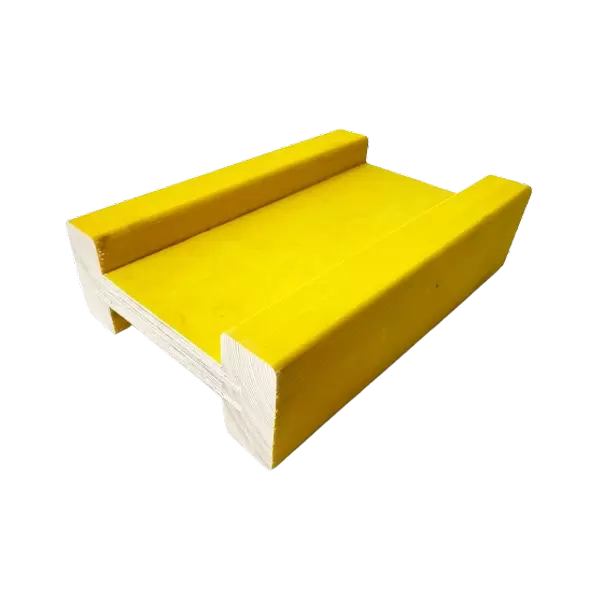

Modern MDF manufacturers are increasingly focused on innovation and sustainability. Shandong Xingang Group Co., Ltd. has long been dedicated to the development of environmentally friendly new materials in the wood industry. Its proprietary Xingang biomimetic adhesive technology achieves zero formaldehyde, zero benzene, and zero harmful substances, setting a new benchmark for green MDF production.

This innovative adhesive has been successfully applied at scale in biomimetic decorative boards, ultra-thin MDF, and biomimetic marine plywood. As a result, Xingang panels not only meet strict environmental standards but also offer antibacterial and antiviral properties along with excellent physical performance.

Building a Sustainable Future with MDF Manufacturers

As global demand for healthier and more sustainable building materials grows, the role of MDF manufacturers continues to evolve. Leading companies are no longer just suppliers of panels; they are partners in creating safer indoor environments and more sustainable living spaces.

Shandong Xingang Group Co., Ltd. works together with global partners to build a green home ecosystem, aiming to deliver products that support human health and environmental responsibility. By choosing MDF manufacturers that prioritize innovation, quality control, and sustainability, businesses and consumers can contribute to a more sustainable future while enjoying high-performance wood-based materials.